|

All Malmet products are manufactured in the facility at Leeton NSW, which is ISO 9001:2015 and ISO 13485:2016 Certified.

Malmet Bedpan, Urinal Bottle Washer Disinfectors comply with AS 4187:2014, ISO 15883-1/3:2006, ISO 15883-5:2005,

Reprocessing of reusable medical devices in Health Service Organisations, and the relevant parts of ISO 15883 for Washer Disinfectors.

The equipment has been microbiologically tested as per recommendations outlined in ISO 15883 by an independent NATA Certified Laboratory to ensure the wash efficacy

is satisfactory for the intended load.

Malmet Energy Saver Bedpan Washer Disinfector

Designed in Australia with patented innovations.

Malmet Energy Saver Bedpan Washer Disinfector range is the most efficient and effective method of cleaning and disinfecting bedpans and urine bottles.

Independently micro tested, Malmet machines are proven to inactivate organisms, bacteria and viruses, found in bedpans and bottles.

Key Points of Interest

- Energy saving — Low water and power consumption

- Large capacity — 2 urinal bottles and 1 bedpan per cycle

- Can accommodate large slipper pans

- Efficient and low electricity use — Available in 10 Amp & 20 Amp, single phase

- Pre-wash detergent cycle

- Hands free operation — To minimise infection risk

- The door safety is factory set; an obstruction will cause the door to re-open when the obstruction is detected.

This is designed to protect the integrity of the machine and the articles within.

- Minimise hot water use — Steam DisinfectionSteam Disinfection to higher Ao600 level as recommended by AS4187:2014 ⁄ ISO15883

- Non-vented — Stand alone

Standards compliance and testing

Features for Control Infection

- A total hands–free procedure for each disinfecting cycle — utilizing sensor beam breaks.

No need to touch the machine or control pad.

- The internal chamber is cleaned and disinfected during each cycle.

- Steam and detegent disinfection of equipment is above the Australian Standards in temperature generation and length of cycle.

- Hands Free Operation – Zero Contamination – No infection risks to patients or staff.

- Odourless disinfection – No bacterial masking or fragrance sprays required as no odours or smells remain.

No disposable or consumable inventory

- Bed pans and urinal bottles are disinfected ready–for–reuse.

- No disposable container holders to wash or disinfect.

- No additional waste imposed on the local government community’s sewerage system.

- No worrying about possible imposition of surcharges for excess waste into the sewerage system.

- Not excluded for use by any local authority or council.

- Only detergent and natural body waste is flushed into the sewer.

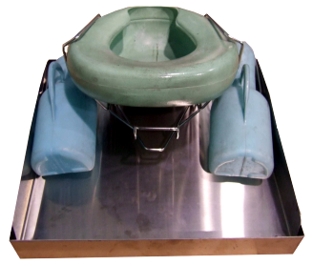

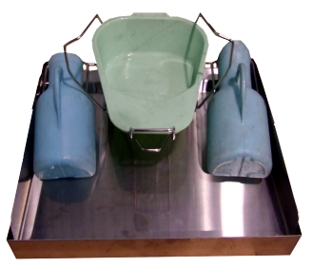

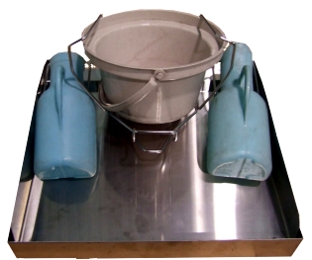

Suggested item positioning in the chamber

Some layout suggestions for items inside the Chamber

Videos — ESD Washer Disinfector

Universal Cradle is fitted to all ESD

Universal Cradle is fitted to all ESD Washer Disinfector models

- The Energy Saver Bed Pan Washer Disinfector fitted with a Universal Cradle can accommodate:

- Standard size bed pans

- Standard commode bowls

- Standard male and female urine bottles

- Most plastic urine bottles including male non-spill and female adaptor

- Large and regular size slipper pans

- Product Code to upgrade old models: 91-3053

- Universal Cradle Brochure

Models and Accessories

Models

| Product Code |

Description |

Trap |

Power |

Power Use (kwh) |

| ES91-1002 |

Washer Disinfector ES915 |

“S” |

20A |

0.300 |

| ES91-1007 |

Washer Disinfector ES915 |

“P” |

20A |

0.300 |

| ES91-1022 |

Washer Disinfector ES935 |

“S” |

10A |

0.236 |

| ES91-1027 |

Washer Disinfector ES935 |

“P” |

10A |

0.236 |

| Product Code |

Description |

Average Cycle Times (minutes) |

Water Use (litres) |

| ES91-1002 |

Washer Disinfector ES915 |

5.30 |

36 |

| ES91-1007 |

Washer Disinfector ES915 |

5.30 |

36 |

| ES91-1022 |

Washer Disinfector ES935 |

7.50 |

35.05 |

| ES91-1027 |

Washer Disinfector ES935 |

7.50 |

35.05 |

| Accessory |

| 91-5056 |

1 litre Jug Holder Cradle to suit ES disinfector |

Recommended positioning of the free-standing ESD

| Positioning of Bedpan Washer Disinfector (Freestanding Model) |

| Model |

Placement |

Access Required |

Device Dimensions |

Height

(mm) |

Width

(mm) |

Depth

(mm) |

| ES91- |

Freestanding |

Both Sides |

1305 |

595 |

660 |

| For Freestanding model, please allow sufficient room for servicing purposes.

Recommended space requirements 200mm on either side and 150mm at the rear of the unit. (see installation manual) |

Component Identification Views — Spare Parts codes ⤵

Service connection requirements for ESD

| Service Connections |

| Model |

Cold Water |

Soil Line |

Electrical |

| ES91-1002 ⁄ ES91-1007 |

GB¾ Male |

100mm ‘S’ or ‘P’ |

240V 1 phase @ 20 amps 50 hertz |

| ES91-1022 ⁄ ES91-1027 |

GB¾ Male |

100mm ‘S’ or ‘P’ |

240V 1 phase @ 10 amps 50 hertz |

No external vent pipe work is required as the device is designed to condensate all visible steam internally.

NOTE: Plumbing connection must comply to AS3500 |

Power and Water Consumption for ESD

| Power and Water Consumption Data |

| Model |

Avg Cycles per ⁄ Hr |

Avg Cycle min ⁄ sec |

Avg kWh per cycle |

CW Avg Lt per cycle |

| ES91 20A DET |

11 |

5.3 |

0.300 |

36 |

| ES91 10A DET |

7.7 |

7.5 |

0.236 |

35.5 |

| NOTE: Values may change due to operating and supply service conditions. |

Specifications 20A ⁄ 10A model ESD Washer Disinfectors

Electrical Rating

ES91-1002 ⁄ ES91-1007 |

Volts

Phase ⁄ Hertz

Amps

|

240

1 ph ⁄ 50 Hz

20A

|

| Environment operating conditions |

Temperature

Relative Humidity

|

+10°C to +25°C

+30% to 70%

|

| Element (ES91-1002 ⁄ ES91-1007) |

Rated

Overtemp protection

|

4.5Kw

Thermal cut-out switch 3 pole set point 115°C Manual reset

|

Electrical Rating

Models ES91-1022 ⁄ ES91-1027 |

Volts

Phase ⁄ Hertz

Amps

|

240

1 ph ⁄ 50 Hz

10A

|

| Element (ES91-1022 ⁄ ES91-1027) |

Rated

Overtemp protection

|

2.2Kw

Thermal cut-out switch 3 pole set point 115°C Manual reset

|

| Fuse: Transformer |

Cylinder type

|

F3.15AL 250V

|

| Fuse F1 : Power supply PCB |

Cylinder type

|

T315mA 250V

|

|

Spray System

|

Main Wash

Cool Down

|

1 x rotating 180° nozzle

2 x fixed 60° nozzles

2 x fixed 0° uninary nozzles

1 x fixed 60° nozzle

|

|

Wash Chamber

|

Material

Capacity

|

1.2mm Stainless Steel

2 x urinal bottles + bed pan + lid OR

2 x urinal bottles + commode bowl + lid OR

2 x urinal bottles + small commode bowl + lid OR

2 x urinal bottles + slipper pan + lid OR

2 x urinal bottles + large slipper pan + lid

|

Soil Line Connection

Complies to AS 2887 & AS ⁄ NZS 3500.2:2003

|

Type

Size

|

‘S’ or ‘P’ Trap (6mm PE)

100mm ID

|

Backflow Prevention

AS 2845.2 – 1996 |

Air Gap (RAG)

|

|

| Water Supply Cold |

Temp – Pressure (Static)

|

5 – 25°C @ 100 – 400kpa

|

Water Inlet Valve connection

WRAS Certified |

Solenoid 240V

|

GB¾ Male

|

Hose – valve to Cold Water Tank

WRAS Certified |

Stainless Steel Braided

|

10mm

|

|

Frame

|

Material

|

Stainless Steel

|

Detergent

ARTGC Class 1 |

Malmet specific (5Lt)

|

Detergent concentrate Caustic Alkaline

|

Environmental conditions

Transport and Storage

|

Fragile, Keep away from rain

Temperature

|

Do not stack

-5°C to +50°C

|

Return to top of page Return to top of page

|

Return to top of page

Return to top of page

Email for more information.

Email for more information. )

)